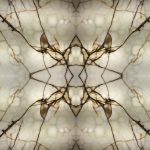

Description: Two consecutive stone slabs are cut and polished to create mirror-image patterns.

Appearance: Like an open book, where the veining and patterns align symmetrically.

Usage: Often used for dramatic visual effects in large surfaces like walls or countertops.

Description: Two consecutive stone slabs are cut and polished to create mirror-image patterns.

Appearance: Like an open book, where the veining and patterns align symmetrically.Usage: Often used for dramatic visual effects in large surfaces like walls or countertops.

Description: Four slabs are arranged to create a continuous pattern across them.

Appearance: The slabs are aligned so that the patterns flow seamlessly, forming a cohesive design.

Usage: Ideal for creating a balanced and symmetrical look in larger spaces.

Description: Small, scattered spots or flecks.

Examples: Typical in many granites.

Description: Circular or swirling patterns.

Examples: Often seen in onyx and certain marbles.

Description: Lines or streaks of contrasting color.

Examples: Prominent in marble.

Description: Smooth and uniform, with minimal patterns.

Examples: Some limestones and granites.

Waveless patterns can be achieved by cutting in a direction that minimizes the exposure of these natural undulations, resulting in a smoother and more uniform surface.

Description: Flowing, undulating lines.

Examples: Common in marble and onyx.

Wavy patterns can be created by cutting the slabs along the grain or along a particular direction that reveals the natural undulations in the material.

A polished surface is bright and shiny, providing a mirror-like effect and the finest edge for tiles. Created through repeated abrasive treatments, this finish suits nearly all stone types and is widely used in Iranian stone factories. Polished tiles are perfect for indoor settings, countertops, and benchtops, but are not ideal for outdoor use because of lower slip resistance. It is the preferred finish for marble.

Honed finishing is typically used for limestone, as many types cannot be polished. This finish results in a smooth surface with a dull or mildly reflective look, offering less gloss than a polished finish. In high-traffic areas, floor tiles are often honed instead of polished.

A leathered finish is achieved by using diamond-tipped brushes on a stone surface, creating a soft, textured appearance similar to leather. This technique is often applied to stones with natural holes, such as travertine, certain marbles, and some granites. During the process, the edges of these holes are smoothed, enhancing the stone's tactile quality.There are two variations of leathered finishes:

Polished Leathered and Honed Leathered.

Polished Leathered combines texture with a glossy sheen, offering a unique, shiny appearance while preserving the stone's natural undulations.

Honed Leathered maintains a matte finish, providing a softer, more understated look.

A sandblasted finish is created by blasting a stone surface with high-pressure sand, resulting in a rough, matte texture. This finish is particularly useful for exterior cladding, walkways, and applications requiring a non-slip surface. The sandblasting process removes saw marks and creates a smooth surface with fine, nearly invisible circular marks, giving the stone a subtly scratched appearance. Despite this, the texture feels pleasant to the touch.

Sandblasted stone colors tend to be more muted compared to other finishes. Commonly applied to sandstone, this finish is an excellent choice for exterior applications due to its durability and slip-resistant properties. Known for combining functionality with aesthetic appeal, the sandblasted finish is sometimes referred to as a grit blasted finish, offering the same benefits and visual characteristics.

Tumbled stones are created by placing them in a drum with abrasives, sand, pebbles, and water. This process gently wears down their edges and surfaces, resulting in an aged, weathered appearance. Often used for tiles, pavers, and decorative elements, tumbled stones give the impression of centuries-old use. The process imparts a unique, rustic charm to various stones, making them ideal for both interior and exterior design applications.

A flamed finish is achieved by exposing the stone surface to high-temperature flames, causing it to burst and become rough. This finish is ideal for exterior applications like walkways and pool surrounds due to its excellent slip-resistant properties. The process involves directing flames at the stone, causing thermal shock that dislodges crystals, particularly in granite. The resulting surface is rough, non-slip, and generally muted in color, effectively concealing defects and tone variations. Additionally, oxidation can turn yellow materials orange or red, adding a unique aesthetic appeal.

By using high-pressure abrasive brushes, the original surface—whether honed, sandblasted, flamed, or sanded—becomes smoother. This treatment enhances the natural stone's colors, making them more vivid. The resulting surface retains a slightly rough texture, depending on the initial finish.

A bush hammered finish is created by mechanically hammering the stone surface to produce a pitted, textured look. This involves using a mechanical hammer that strikes the stone, leaving small indentations. The texture and appearance depend on the hammer's size and the number of points it has. This finish is ideal for both interior and exterior applications, especially for paving or walkways, where a non-slip surface is essential.

A split face finish is produced by mechanically splitting the stone with a guillotine, revealing a rough, rocky texture. This process exposes the stone’s natural, rugged surface, giving it an authentic, rustic look. Commonly used for wall cladding and decorative features, split face finishes provide a natural, earthy aesthetic that enhances the visual appeal of both interior and exterior spaces.

An antiqued finish is achieved through treatments like brushing or acid washing, giving the stone an aged, worn appearance. Ideal for flooring, paving, and areas desiring a vintage look, this finish can be created using machines similar to commercial washers for smaller items. For larger pieces, the stone is flamed and then brushed with abrasives. This finish not only imparts a weathered look but also enhances its rustic charm over time.

A sawn finish is created by cutting the stone with diamond disc teeth, resulting in a somewhat rough surface with small furrows and undulations. This finish lightens the stone and gives it a matte tone, making it ideal for external applications such as paving, steps, pathways, driveways, and patios. The process uses diamond gang saws, diamond wire saws, or block cutters to saw granite, marble, sandstone, or travertine blocks into slabs. While the surface is generally smooth, it may display subtle blade or saw markings, enhancing its natural character and appeal.

A chiseled finish is created by breaking the stone with a hammer and chisel. The resulting surface can range from very rough to slightly irregular, depending on the chisel type and artisan's skill. This versatile finish can be applied to any stone, adding a unique, textured appearance.

An acid-washed finish is achieved by applying a solution of hydrochloric or muriatic acid to stone, creating a textured, matte appearance that enhances the stone’s natural colors and patterns. This slightly rough, non-slip surface is ideal for outdoor applications like pool decks, patios, and walkways. It adds a rustic, aged look, suitable for stones such as limestone, marble, and granite. Regular maintenance, including sealing and cleaning, is essential to preserve its appearance and durability.

Epoxy-treated stone undergoes a multi-step process to enhance its visual and physical properties. First, the stone is honed for a smooth surface, ready for resin application. It is then dried in a specialized oven, followed by additional resin application and drying. Finally, the stone is polished to achieve a glossy finish. This process enhances the stone’s visual appeal and durability, making the tiles more resistant and aesthetically pleasing.

A natural finish showcases the stone as it is extracted from the quarry, without additional treatment. The final look depends on the stone’s inherent characteristics and the quarrying process. This finish is perfect for cladding and both irregular and regular cubic stone, highlighting the raw beauty and unique qualities of the material.